Add time:2025-11-06

Add time:2025-11-06 clicks:

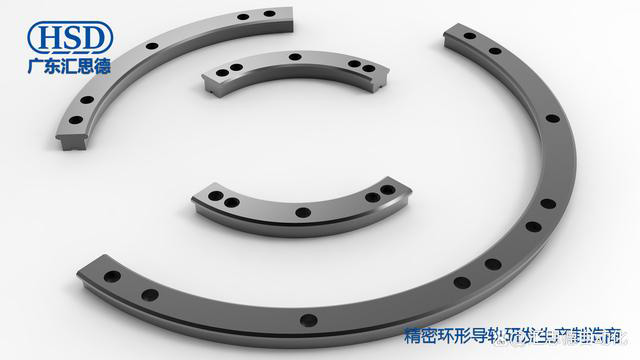

clicks: Arc guide rail is an indispensable part of the spliced circular guide rail, and the arc guide rail is the curve-turning part of the entire circular guide rail. The arc guide is actually a part of the circular guide rail, and a conventional circular guide line requires at least one circular guide rail.

Common arc guide rails arc track section width: 25mm, 44mm, 76mm;

The width of the arc track section of the arc guide rail is the same as the application width of the common guide rail. The 25mm wide arc guide rail is usually used for light loads, the 44mm wide arc guide rail is used for medium loads, and the 76mm wide one is often used for heavy loads. Of course, the arc guide rail also has other customized width sizes, such as: 18mm, 20mm, 38mm, 88mm, etc., but because of the low application and high cost, it is less used, and it is difficult to match the spare parts of different arc guide manufacturers, and the versatility is not high, so almost few manufacturers produce applications.

Common sizes of arc guide diameter are:

A. The available diameters for the light-load 25 mm arc guide rails are Φ200 mm, Φ255 mm, Φ300 mm, Φ351 mm, Φ400 mm, Φ468 mm, Φ500 mm, and Φ600 mm.

B. The optional diameter for the mid-load 44 mm circular arc guide rail includes Φ468 mm and Φ612 mm.

C. The available diameters for the heavy-duty 76 mm arc guide rail are Φ800 mm, Φ1000 mm, and Φ1200 mm.

Light-loaded circular guide rails are small, so the turning radius can also be made smaller. It should be noted that the turning radius is small, and the running speed should not be too fast. Otherwise, the centrifugal force will be too large, which will exceed the safe operating range of the guide rail, increase the noise, deteriorate the stability, accelerate the wear and tear, and even seriously damage the slide or annular guide rail.

The diameter of the conventional track of the arc guide rail is as above. In addition, the diameter of the large ring rail commonly used by Huiside Automation is also in sizes such as φ 1300, φ 1500, φ 1600, φ 1700, and φ 1800mm.

Common arc guide rails arc track turning angles are: 90 degrees, 180 degrees, 270 degrees, 360 degrees;

To put it bluntly,The arc-shaped guide rail is a segment derived from a circular rail, with its dimensions and angular span being customizable according to specific requirements. From a practical application standpoint, 90-degree and 180-degree arc-shaped guide rails are the most widely adopted due to their ease of integration and functional versatility. The 90-degree variant is primarily utilized in rectangular and square configurations, while the 180-degree version is commonly employed in elliptical guide rail systems. A full 360-degree configuration constitutes a complete circular guide rail.

Unlike traditional linear guide rails, circular guide rails have outstanding characteristics such as high rigidity, high positioning accuracy, good anti-pollution ability, and higher operating speed, which can well meet the precision automation needs of modern factories.

Circular arc guide compared with traditional linear guide rails, it has its unique advantages:

● Suitable for use in harsh environments, from dust-free to dusty

● Lower maintenance and replacement costs

● Longer service life